Global Digital Twin Market Seeing (More Than) Double

/With enhancements in AR/VR, connectivity, and processing power, the adoption of digital twins is exploding—and the trend is only getting started.

Million Insights estimates that the digital twin market size—valued at $2.26 billion in 2017—is anticipated to reach $26.07 billion by 2025.

The massive growth is being fueled by the automotive, transportation, and commercial applications...with a little push from COVID-19 and resulting restrictions.

Let’s Double Back on Digital Twins

There are a lot of definitions of what a digital twin is. Here’s one we like from ARC Advisors:

“A digital twin is a dynamic virtual representation of a physical entity using real-world data. The representation can take the form of a mathematical algorithm, machine learning, or 3D model.”

Digital twins can map at any level, from a single component to an entire operation—collecting data, issuing alerts, running diagnostics, and giving operators the information they need to maintain and repair assets.

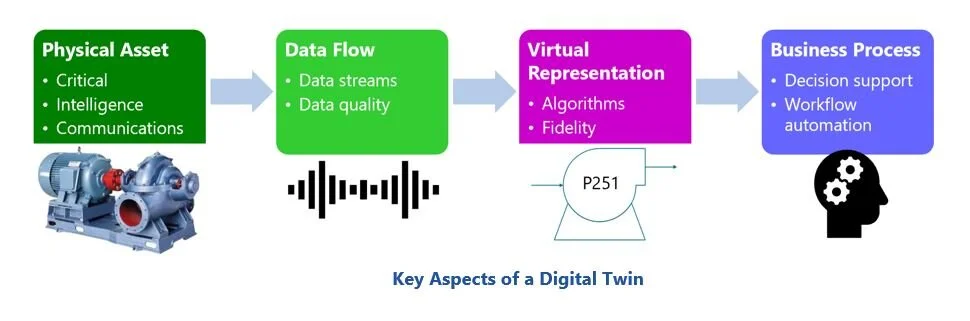

Again from ARC Advisors, here are the components of a digital twin and how they work together.

Greg Withers, projects modernization and transformation director for BP, said on a recent panel, "The digital twin enables realistic simulation and easy access to all information, and in one place. It enables planning, remote operations, monitoring and support which would traditionally require personnel to be physically [at], or at least very near, the site."

How Industrial Enterprises Are Using Digital Twins

Digital twins are a big up-front investment—getting more and more accessible with off-the-shelf solution—but enterprises are seeing the benefits to the bottom line, as well as to safety, uptime, and efficiency.

Jim Purvis, vice president of operations for Worley Digital, said, “Digital twins can increase the operational efficiency in the uptime of a facility as well as in the maintenance area, providing even more opportunities to accrue value.”

General Electric uses digital twins to assess the maintenance and operational life of jet engine components. They even have a feed of issues prevented and resolved, both for GE and its customers, using digital twin virtual technology.

At the Industrial XR Forum, Schlumberger shared a full use case on how they are increasing efficiency and lowering costs at the wellsite on a daily basis with drones, 3D, AR, and digital twins in an integrated technology workflow.

BP has been using digital twins in its operations for years. APEX, BP’s simulation and surveillance system, creates a virtual copy of all BP’s production systems throughout the world. In 2018, BP Gulf of Mexico Petroleum Engineer Carlos Stewart said, "Engineering time has been the biggest payback—a system optimization could take 24-30 hours. In APEX, it takes 20 minutes.”

Enterprises are also using digital twins for more strategic initiatives, including asset management, process control and automation, asset lifecycle information management, product lifecycle management, and more.

“Digital twins can serve as a single source of truth for the collection of data that can generate feedback for continuous improvement downstream, as well as feed insights forward,” said Joe Sawicki, executive vice president with Siemens, in an Electronics Design interview.

#Twinning

All signs point to the use of digital twins in enterprise asset management, monitoring, and repair continuing to expand.

Maybe it’s time to double down.