New Report from Siemens: The Next Era of Industrial Robotics

/Siemens' latest report, Tech Trends 2030: The Next Era of Industrial Robotics, provides an in-depth exploration of how cutting-edge technologies are redefining the industrial robotics landscape. With more than four million robots in operation globally and annual installations exceeding 500,000 units, the industry is at a transformative crossroads. Here’s a summary of the key insights and trends driving this evolution.

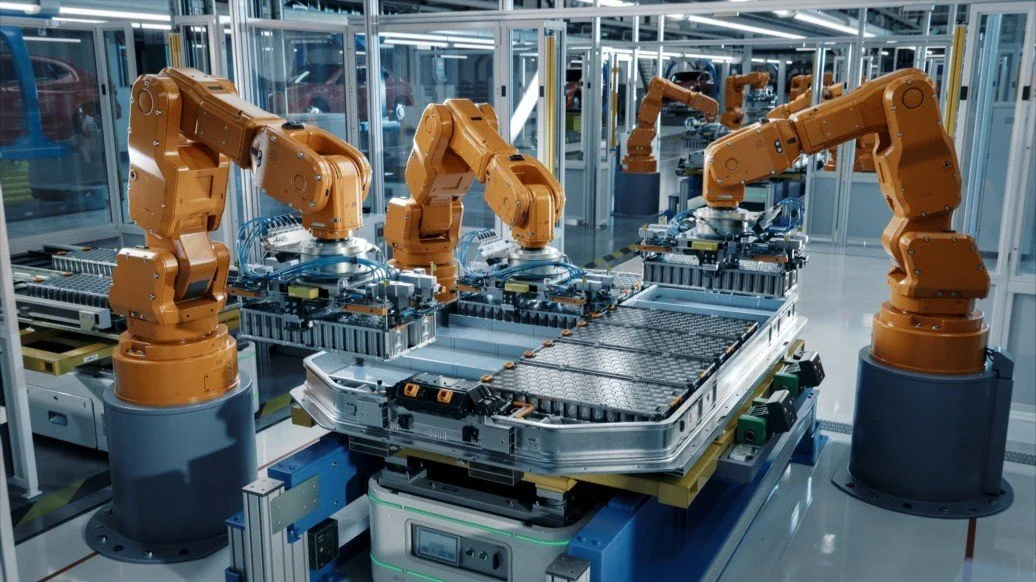

The Shift from Traditional to Collaborative Robots

Industrial robots have long been essential for high-precision tasks like assembly and welding. However, collaborative robots, or cobots, are gaining momentum — now accounting for 10% of new installations. Though not yet fully capable of direct human collaboration, their compact design, ease of programming, and low energy requirements make them ideal for mobile and constrained environments.

Four Key Trends for the Future

AI-Powered Autonomous Robotics: Advancements in AI, such as Siemens’ SIMATIC Robot Pick AI, are enabling robots to adapt dynamically to their environments, paving the way for more autonomous and intelligent systems.

Human-Robot Partnerships: Collaborative robots and exoskeletons are set to enhance human physical capabilities. Smart mechatronics and advanced AI will enable robots to truly collaborate with and learn from their human counterparts.

Intuitive Interfaces: Natural language processing and generative AI will simplify programming and interaction, making robotics more accessible to engineers and workers alike.

Virtual Training and Operations: Technologies like digital twins and software-defined automation will allow for virtual simulations, reducing costs and risks. These advancements are complemented by the industrial metaverse, promising more immersive interactions.

Impactful Scenarios and Industry Implications

The report outlines transformative scenarios for the future:

Robot Companions: AI-powered robots will assist workers on the shop floor, handling repetitive and hazardous tasks while humans focus on strategic decision-making.

Automation of Automation: Self-optimizing robotic systems will revolutionize production, using industrial metaverse simulations to enhance efficiency.

Cyber-Physical Management Systems: Digital twins and IoT integration will allow robots to execute dynamic, real-world actions based on real-time data.

Localized Manufacturing: Autonomous systems will decentralize production, reducing reliance on global supply chains and enabling local, customizable manufacturing.

Mastering the New Era

Siemens emphasizes a holistic strategy for integrating robotics into manufacturing, highlighting the importance of:

Seamless connectivity between robots and digital platforms

Leveraging cloud and edge computing for real-time responsiveness

Implementing software-defined automation and digital twins for adaptability

Prioritizing workforce upskilling and ethical compliance

As robotics converges with AI, IoT, and the industrial metaverse, Siemens foresees a future where dynamic, agile, and sustainable production becomes the norm. This report underscores the critical need for industries to adopt innovative technologies and strategic foresight to stay competitive.

Download the full report on the Siemens website.

✏️📅 Save the date for the Energy Drone & Robotics Summit, June 10-12, 2025! It's the place where North American robotics leaders will gather in 2025 to discuss the current deployments, and see what's next for industrial robotics. Get involved today!