Reimagining Industry: Kevin O’Donovan on the Power of the Industrial Metaverse

/from Youtube

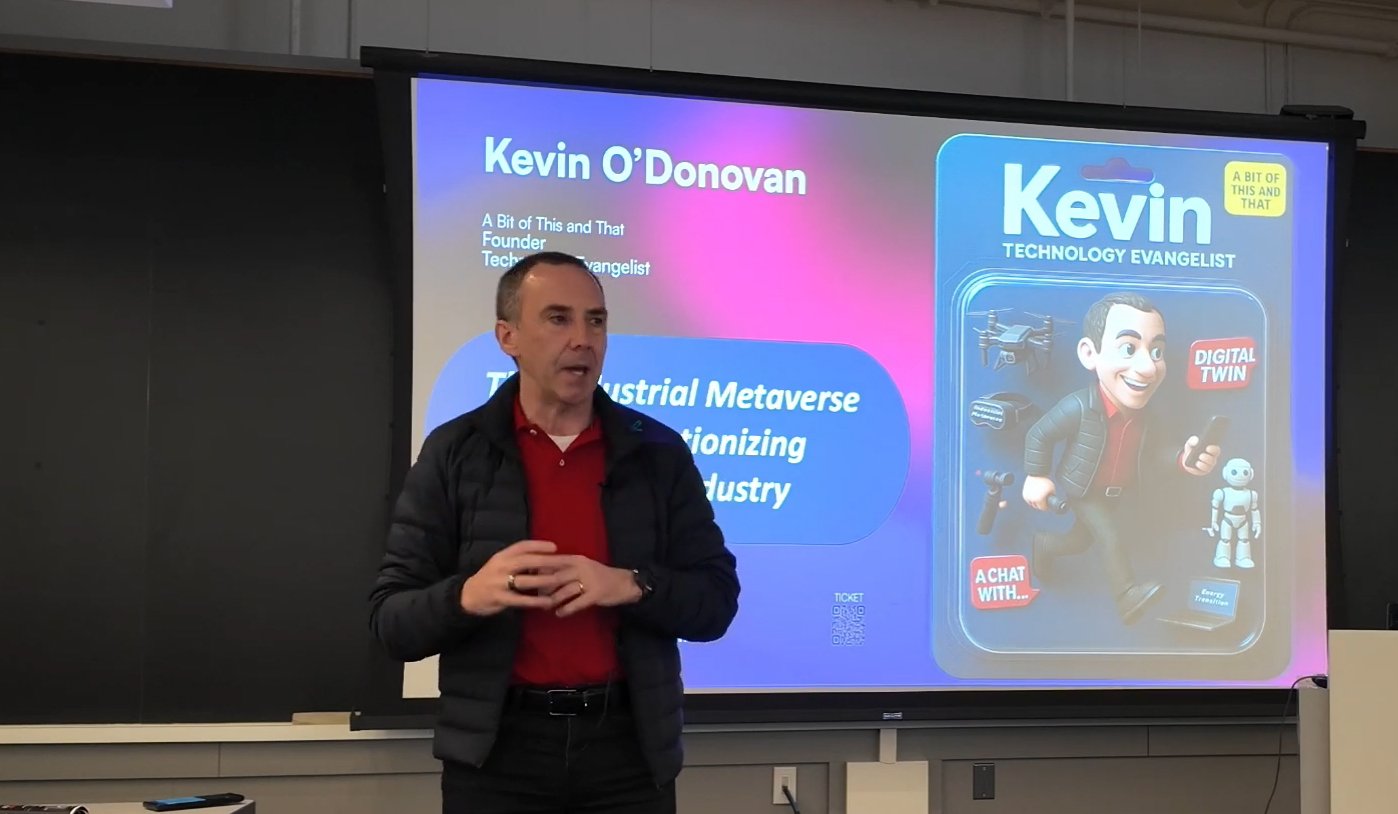

At the HarvardXR 2025: The Augmented Self event, technology evangelist and friend of Industrial IMMERSIVE Kevin O’Donovan took the stage to share a compelling vision of how the industrial metaverse is reshaping not only extended reality (XR), but also the future of industry and energy. Drawing on his extensive experience with companies like Intel and Siemens, O’Donovan offered an unfiltered, pragmatic view of what’s next for industrial innovation.

Why "Industrial Metaverse" Matters

O’Donovan opened by explaining why he believes “industrial metaverse” is the most fitting term to describe the sweeping changes underway. “It’s digital first,” he said, emphasizing that modern industrial development begins with digital design—before anything is physically built.

This shift isn't just about flashy new tech; it's about responding to major macroeconomic forces like onshoring, near-shoring, and supply chain disruption. According to O’Donovan, “The only way we’re bringing manufacturing back to any country is autonomous and robots and designed digitally first period.”

This digital-first mindset spans the entire industrial lifecycle—from factory design to software programming, real-time data optimization, and customer-driven reconfiguration. Traditional mass production is giving way to mass customization, where a “batch size of one” is becoming the norm.

XR as Part of a Bigger System

While many see XR as a standalone solution, O’Donovan warned against that siloed thinking. XR’s real power lies in its integration with a broader platform that connects digital twins, AI, simulation, and real-time data. “If I want a new digital twin,” he said, “I want to see what the factory looks like right now, I put on a headset, hit return, and I am looking at the latest version of that factory from Friday afternoon.”

But XR won’t realize its full potential until it’s woven into the larger digital thread that binds all parts of industrial systems together. Tools like NVIDIA’s Omniverse platform are starting to make that kind of integration possible by enabling collaborative, physics-based simulation across departments and disciplines.

Not Just Digital Twins—Digital Threads

O’Donovan spent significant time demystifying digital twins. In his view, a single digital twin isn’t enough. Industry requires multiple interoperable twins tied together through what’s known as the digital thread. He emphasized the need for simulation, not just visualization: “Suppose I want to increase production by 20% in a month's time. Can I do that? Can I run the simulations? And when I say simulation, can I run everything to figure out will anything break?”

From factory layout to materials analysis to predictive maintenance, these connected digital models must simulate real-world physics and performance. And increasingly, they’re being used to train AI—another driver breaking down organizational silos. “The biggest driver of breaking down data silos in the world is every CEO is turning around to their company saying, ‘What are we talking about AI?’”

The Role of GenAI and Edge Computing

The convergence of generative AI, edge computing, and XR is also reshaping how quickly and easily virtual industrial environments can be created. With large language models (LLMs) and platforms like Unity and Unreal, what used to take months of technical training can now be spun up with a well-crafted prompt.

O’Donovan noted, “You needed real skills to create a virtual world...now I can go to chatGPT or Claude and boom. Is it perfect? No. But it’s a lot better than spending six months trying to learn a language.”

He also pointed to major developments in edge computing, especially in industrial robotics and smart meters, as a critical enabler for real-time XR applications. Agents powered by edge-based AI are now competing to make optimized decisions locally—minimizing latency and reducing dependence on cloud computing.

XR Is at a Tipping Point—If It Can Escape Its Silo

O’Donovan acknowledged that XR in industry has long struggled to gain traction, often relegated to isolated pilot projects. He said the process often looks like:

We took data of our asset from a snapshot in time

We gave that data to a third-party partner

After three months, they came back with an app

There was a big learning curve

Our asset no longer looks like the data we provided

We tried XR, it didn’t work

Unless XR is continuously connected to the latest models, real-time data, and enterprise systems, it risks becoming obsolete on arrival. XR must become a live window into digital operations—not a static app.

The rise of lightweight tools like mobile lidar scanning and real-time spatial capture is helping make this vision more attainable, but only if those tools feed into integrated platforms.

Final Thoughts

While the challenges are real—especially human resistance to change—O’Donovan closed with a call to action. “If you think the pace of change is moving fast right now, my advice to you all is buckle up. We’re just getting started.”

His talk served as both a roadmap and a reality check. The industrial metaverse isn’t just an emerging concept—it’s the architecture underpinning the future of intelligent, resilient, and responsive industry. And XR, when fully integrated, is a critical part of making that future visible and actionable.

You can read more from Kevin on his LinkedIn.