Supercharging Field Data Operations for Energy, Engineering, and Industrial Projects

/At last year’s Industrial IMMERSIVE Week, Michael Dejesus of Cintoo shared his expertise in the session, "Supercharge Your Field Data Capture, Organization, and Sharing for Energy, Engineering & Industrial Projects." His presentation highlighted the growing importance of reality capture technology and its transformative role in asset management, digital twins, and cost-saving workflows.

Industrial IMMERSIVE 2025 is next week! There’s still time to register for the most exciting industrial emerging tech event.

The Power of Reality Capture in Industrial Workflows

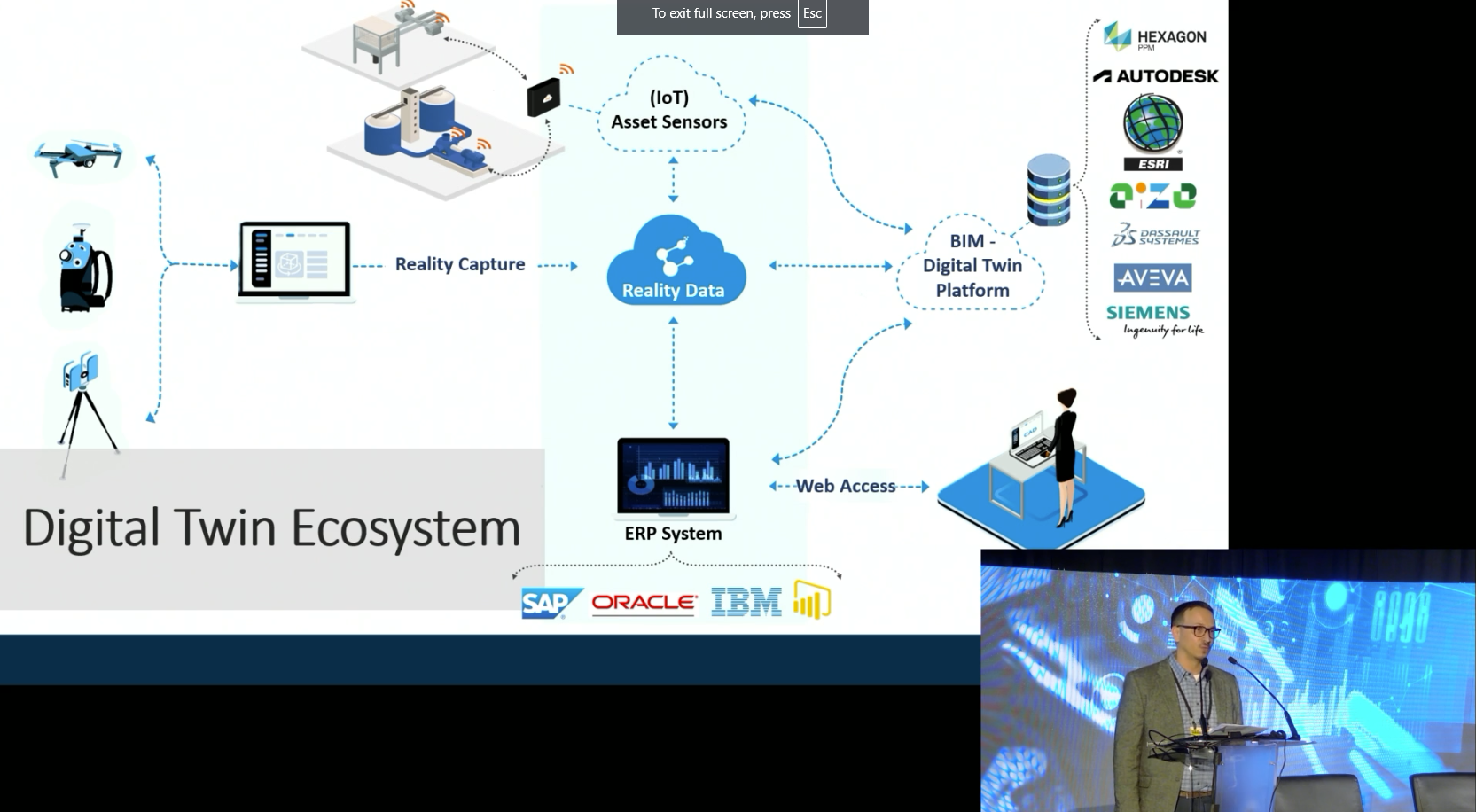

Dejesus opened by emphasizing the critical role of reality capture in digital twin implementation.

He explained: "There is a fundamental piece of digital twins that I think is important and it lies in the dynamic behavior between the data lakes and their source files. So to me, a digital twin isn't just a mere consolidation of data, it is a dynamic integration between the two."

He pointed out that digital twins are only as accurate as the data they receive, making advanced capture technologies like 360-degree photos, photogrammetry, and mobile scanning essential. Dejesus also discussed the rise of wearable scanning technology, such as neck braces and backpacks, that enable seamless data collection.

ROI of Reality Capture: A Case Study in Oil & Gas

A compelling example came from a major oil and gas company that manages 34 production offshore rigs, 16 refineries, and 80,000 pipelines and terminals. By integrating scan data into their maintenance workflows, they achieved millions in cost savings and significantly reduced their carbon footprint.

Dejesus shared an eye-opening result: "Since 2018, just from doing inspections via scan data, they’ve saved millions of dollars just from not having to take helicopters as much to their offshore rigs. The reduction of that also ended up reducing their carbon footprint and the costs associated with that."

One of the biggest wins? A 92% reduction in turnaround shutdown costs, thanks to reality capture’s ability to simulate repairs and maintenance before execution.

Asset Tagging with AI and CAD Models

Dejesus described the industry’s paradigm shift in asset tagging, where AI-assisted tagging and CAD models drastically cut down the time spent on manual tagging.

He detailed three key methods used in Cintoo’s platform:

Manual Tagging – Assigning unique IDs, GIS locations, and hyperlinks to scanned assets

CAD Model Integration – Overlaying models onto point cloud data to create structured asset tags

AI-Assisted Tagging – Training AI to recognize specific industrial assets, reducing tagging time and human error

"With reality capture, the minimum reduction in time spent was 50% and project cost savings was a minimum of 30%. These are minimums we're talking about here. This isn't a particular use case; these were found in studies. 50% time savings, 30% direct cost savings. So pretty significant."

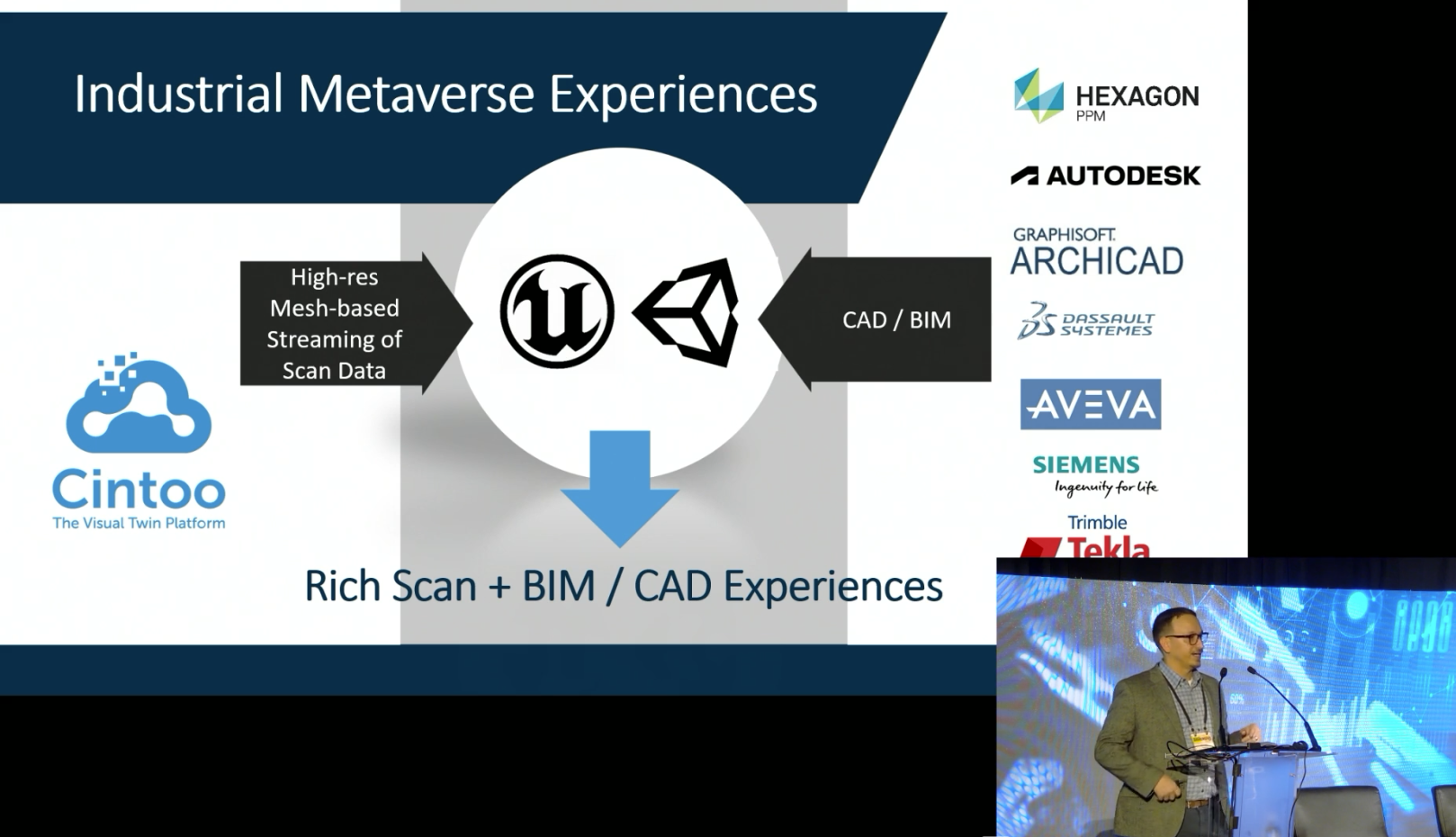

Bringing Industrial Assets into the Metaverse

One of the most exciting innovations Dejesus showcased was Cintoo’s industrial metaverse streaming technology. Unlike traditional methods, which require time-consuming data conversions, their approach enables direct server-to-server streaming of scan data into game engines.

"Traditionally when someone goes to make a point cloud into a mesh and then the mesh into a video game engine, it loses all of its data behind it, it loses its scalability, it loses its coordination. And the process of doing that has to be repeated if any changes happen. So with this ecosystem and the streaming capacity, turning point clouds into meshes into game engines now takes five minutes where traditionally it'd be like five weeks. And there’s no loss of data, which is huge for the mesh itself."

This breakthrough allows industrial teams to visualize, measure, and analyze assets in real time without data loss, making remote collaboration more seamless than ever.

More Industrial IMMERSIVE Tech

Dejesus’s session was a must-watch for anyone interested in leveraging reality capture to drive efficiency, reduce costs, and improve asset management. If you missed it, you can watch the full presentation on demand.

And don’t forget—Industrial IMMERSIVE is coming back! If you want to stay at the forefront of digital transformation in energy, engineering, and industrial projects, make sure to register for this year’s event and join the conversation.